Calibration – Definition, Function and Importance for Sensor Applications

Calibration is a key process that ensures measuring instruments operate within defined accuracy limits. It plays a vital role in verifying the reliability and precision of data in scientific, industrial and medical environments.

What is Calibration?

The definition of calibration refers to the comparison between the output of a measuring instrument and a known reference standard under specific conditions. This procedure helps detect and correct deviations in order to ensure measurement accuracy within acceptable tolerances. Importantly, calibration is not a repair or manual adjustment, but a documented verification of measurement performance.

How Calibration Works

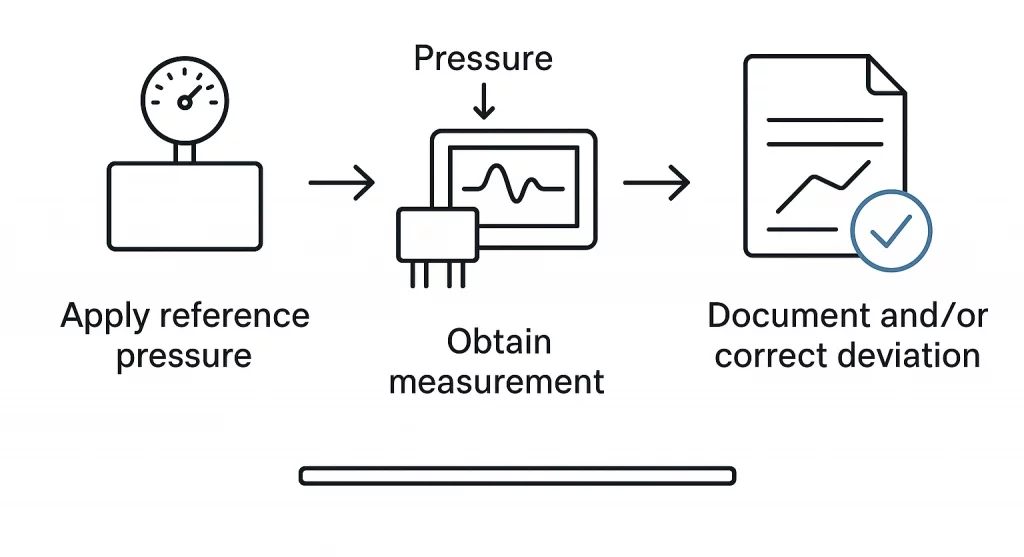

Calibration typically involves three main steps:

- Measurement comparison – A reference value is applied to the measuring device.

- Deviation analysis – The measured value is compared to the known standard.

- Documentation and adjustment – If needed, a correction curve is applied and all steps are recorded for traceability.

This process is essential in all areas where measurement certainty is critical. In the calibration of measuring instruments, it ensures that data collected over time remains accurate, especially in regulated or safety-relevant environments.

Types of Calibration

Several types of calibration exist, depending on industry requirements and the calibration frequency of measuring instruments:

- Factory calibration – Initial calibration done by the manufacturer.

- Routine recalibration – Periodic checks to detect drift or environmental influence.

- ISO traceable calibration – Complies with international standards, often mandatory in quality-driven industries.

Each type helps maintain long-term performance and supports compliance with quality systems.

Why Calibration Matters for Low Pressure Sensors

While calibration is important for all measurement technology, it is particularly critical for low pressure sensors. These sensors, often used in medical ventilation, HVAC systems or laboratory applications, are extremely sensitive to environmental conditions and sensor ageing.

At All Sensors, our low pressure sensors are developed for the most demanding applications. Every sensor undergoes carefully defined calibration routines to ensure precise and repeatable results.

The All Sensors Advantage

All Sensors combines cutting-edge MEMS technology with stringent calibration protocols, developed in-house. This ensures each sensor meets the highest expectations for precision – even at very low pressure ranges.

When you rely on accurate data, trust sensors that are thoroughly calibrated and built for long-term stability.

Ensure Measurement Accuracy – Partner with All Sensors

Whether you need factory-calibrated standard sensors or custom solutions, we’re here to support your success.

Contact us to learn how our technology and calibration expertise can make the difference in your application.