Differential pressure – definition, measurement, and applications

In many technical systems, differential pressure plays a crucial role in ensuring safety, controlling processes, and optimising energy efficiency. Differential pressure is defined as the difference between two separate pressure values in a system. It often occurs across filters, valves, or other components that restrict fluid or airflow. Measuring this parameter helps engineers detect system changes, prevent failures, and maintain reliable operation.

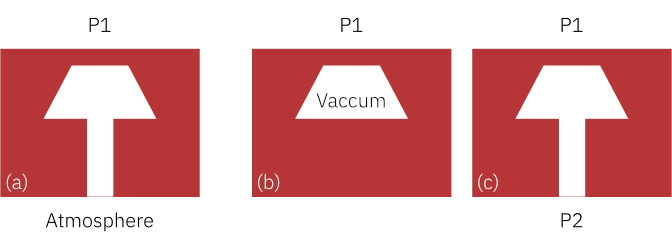

Relative or gauge (a), where the pressure is referenced to the atmosphere

Absolute (b), where the pressure is measured against a reference vacuum sealed inside the chip assembly

Differential (c), where the pressure is measured as the difference between two pressures (delta P or Δ P)

What is differential pressure?

Differential pressure (also called pressure difference or diff pressure) is the pressure difference between two points in a system. Typical examples include the pressure before and after a filter, across a valve, or between rooms with different air conditions. This type of measurement is critical wherever controlled flows of liquids or gases are required.

Common units for differential pressure include Pascal (Pa), bar, and psi (Pounds per square inch). In certain industries, millibar (mbar) or inches of water column (inH₂O) are also used.

Formula for differential pressure

How to measure pressure differential

The formula for differential pressure is straightforward:

Δp = p₁ – p₂

Where:

- Δp = differential pressure

- p₁ = pressure at port 1

- p₂ = pressure at port 2

This pressure difference formula enables accurate monitoring and precise regulation in industrial processes, ventilation, and medical devices.

Pressure differential measurement is usually performed with sensors that feature two separate ports. Each port is connected to a different measurement point. The sensor then determines the difference between the two pressures and provides a signal that can be read by monitoring systems.

Modern sensors use advanced MEMS technology, which ensures long-term stability, high accuracy, and low power consumption. Depending on the application, compact solutions for mobile devices or robust industrial designs can be used.

Applications of differential pressure

Common sources of error

Differential pressure is used in a wide range of industries and technical fields:

- Building services and HVAC: To ensure energy-efficient operation and system safety.

- Industrial process control: Optimising filtration, flow regulation, and pumping.

- Medical technology: Guaranteeing precise delivery of air and gases in respiratory and anaesthesia systems.

- Aerospace: Monitoring cabin pressure and environmental conditions.

- Cleanrooms and laboratories: Keeping contamination under control.

Even with high-quality devices, differential pressure measurement can be influenced by external factors:

- Temperature and humidity fluctuations can alter gas density and impact accuracy.

- Mechanical stress from installation or vibration may cause signal deviations.

- Dust or moisture entering the sensor ports can impair function.

- Long-term calibration drift may occur and require adjustments.

Choosing sensors with temperature compensation and robust construction helps minimise these errors.

How temperature and humidity affect differential pressure

Summary

Temperature changes influence the density of gases, which directly impacts pressure difference values. For example, in sealed systems, a rise in temperature leads to higher pressure readings. Humidity also plays a role: condensation or increased water content in the air can alter sensor output. In sensitive systems, additional humidity control or sensor protection is often required.

Differential pressure is a key measurement in many technical applications. From HVAC and cleanroom technology to medical and industrial processes, it provides reliable data for system monitoring, safety, and efficiency. Understanding the pressure difference formula, knowing how to measure pressure differential, and being aware of potential error sources ensures optimal operation.

Learn more about differential pressure sensors

For practical solutions, please visit our product page on pressure sensors or contact us for tailored support.