Temperature Coefficient – How Temperature Influences Material Properties

The temperature coefficient describes how a physical property of a material changes with variations in temperature. This value is particularly relevant in physics, materials science and electrical engineering – in all areas where materials respond to thermal influences. It indicates whether a property increases or decreases with rising temperature – and to what extent. In electronics, this parameter is a crucial factor in determining the performance and stability of components under changing ambient conditions.

Definition and Calculation

The temperature coefficient is a proportionality factor that describes the change in a physical quantity per degree of temperature variation. It is usually expressed in K⁻¹ (per Kelvin). The formula is:

α = ΔX

X₀ • ΔT

- α represents the temperature coefficient

- ΔX is the change in the measured property

- X₀ is the initial value of that property

- ΔT is the change in temperature

Depending on the property, the coefficient can be positive or negative.

Positive and Negative Effects of Temperature

If a material property increases with rising temperature, it has a positive temperature coefficient. Conversely, if the property decreases, it has a negative temperature coefficient. This distinction plays a vital role in electrical engineering:

- Metals generally exhibit a positive temperature coefficient of resistance.

- Semiconductors and NTCs (Negative Temperature Coefficient thermistors) typically have a negative temperature coefficient, making them ideal for use in temperature sensors.

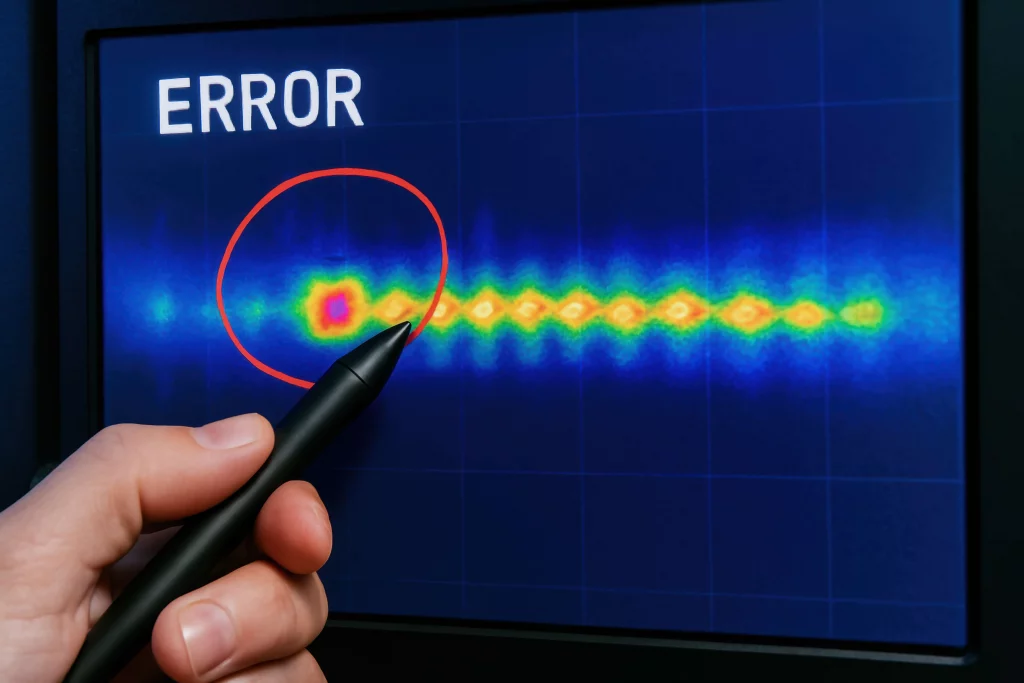

Electrical Resistance

The temperature coefficient of electrical resistance describes how strongly the resistance of a conductor changes with temperature variations. This value is of major importance for circuit design, as thermal fluctuations can lead to deviations in electrical performance.

To calculate the resistance at a given temperature T, the following equation applies:

R(T) = R₀ • [1 + α (T – T₀)]

where:

- R(T) = resistance at temperature T

- R₀ = resistance at reference temperature

- α = temperature coefficient

- T = measured temperature

- T₀ = reference temperature

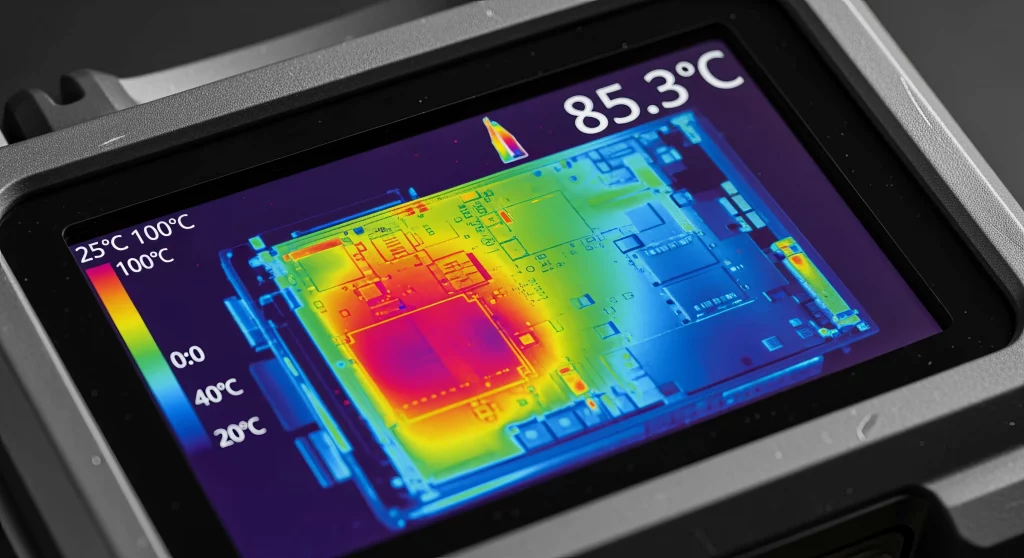

Measurement in Practice

Determining the coefficient is carried out under controlled conditions, typically in climate chambers. The component is deliberately exposed to varying temperatures while its relevant properties are measured. The resulting data provides insights into temperature stability and forms the basis for thermal compensation measures during product development.

Application in Industry

The temperature expansion coefficient plays a key role across numerous technical fields:

- Sensor technology: Sensors are calibrated and optimised with regard to temperature drift.

- Material development: The thermal expansion coefficient determines the selection of suitable materials for changing operating conditions.

- Precision electronics: Temperature-stable components are essential in medical devices, aerospace and metrology.

- Thermal compensation: Engineers deliberately use components with defined temperature behaviour to compensate for system-wide temperature variations.

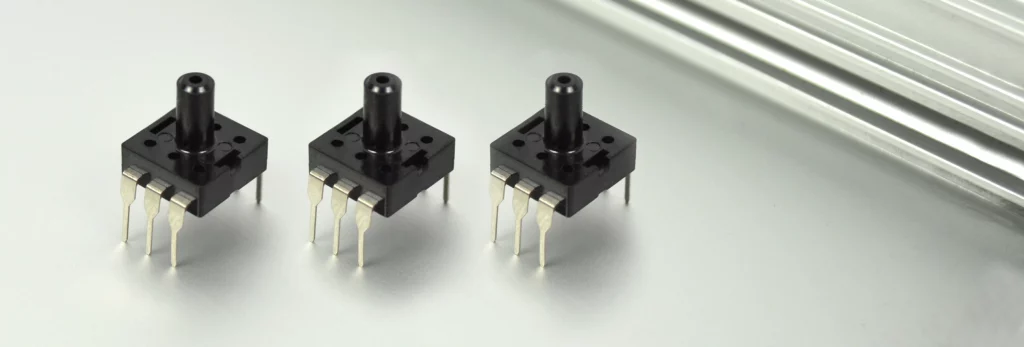

Precision Sensors from All Sensors

All Sensors provides high-precision pressure sensors designed for reliable measurements, even under changing thermal conditions. With many years of experience in sensor technology, we ensure that temperature-related deviations in your measurement systems are minimised.

Conclusion – Why It Matters

Whether it concerns the temperature expansion coefficient in materials or the temperature coefficient of resistance in electronic components – a solid understanding of these parameters improves system design, stability and safety. All Sensors supports you with expertise and tailor-made sensor technology for temperature-compensated and highly accurate pressure measurement.

Contact our experts today for professional advice.