Relative pressure – definition, formula, and applications

In many industrial and scientific processes, relative pressure is the most relevant measurement for control and safety. Unlike absolute pressure, which is measured relative to a vacuum, relative pressure is measured relative to the ambient atmospheric pressure. This makes it particularly practical for everyday use, as it reflects the real conditions under which machines and systems operate.

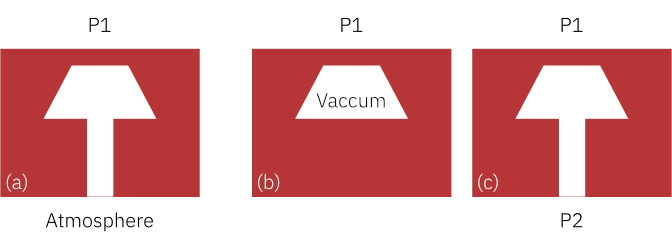

Relative or Gauge (a), where the pressure is referenced to the atmosphere

Absolute (b), where the pressure is measured against a reference vacuum sealed inside the chip assembly

Differential (c), where the pressure is measured as the difference between two pressures (delta P or Δ P)

What is relative pressure?

Relative pressure (also referred to as gauge pressure) is the difference between the absolute pressure of a system and the surrounding atmospheric pressure. A reading of zero relative pressure means that the measured pressure is equal to the ambient air pressure. This concept is widely used because most processes operate under normal atmospheric conditions.

The relative pressure formula is expressed as:

p_g = p_abs – p_atm

Where:

- p_g = relative pressure

- p_abs = absolute pressure

- p_atm = atmospheric pressure

This equation is also known as the relative pressure formula.

How is relative pressure measured?

Relative pressure vs atmospheric pressure

To explain relative pressure measurement: sensors designed for relative pressure have a reference port open to the atmosphere. The diaphragm inside the sensor compares the process pressure with the surrounding air pressure and outputs the difference. This straightforward principle explains why relative pressure is so widely applied in practice.

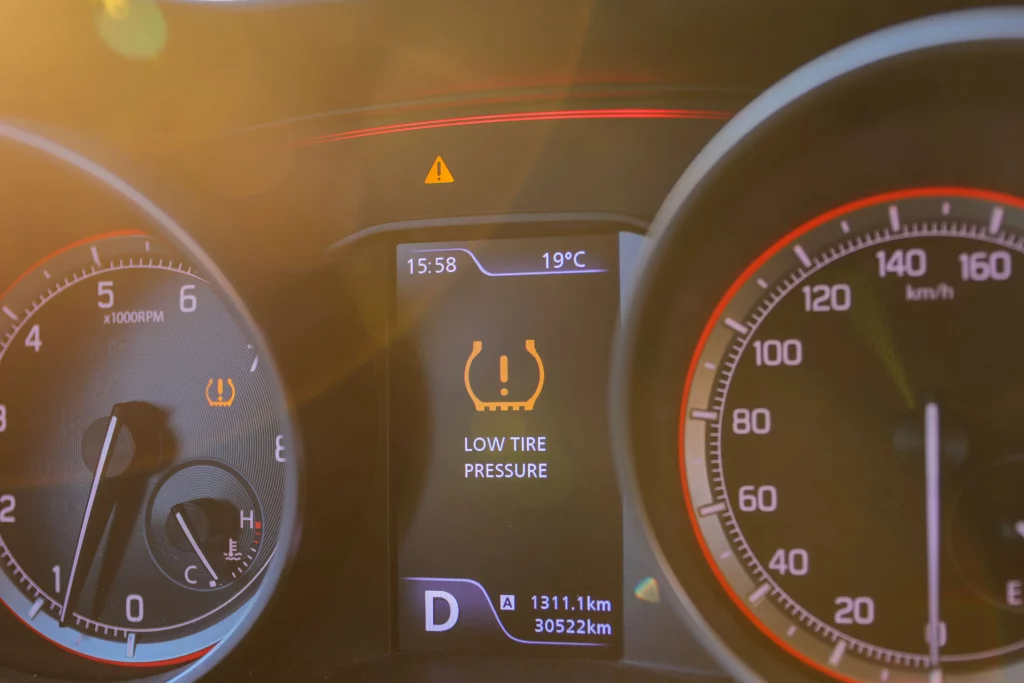

It is important to understand the distinction between relative pressure and atmospheric pressure. Atmospheric pressure is the force exerted by the surrounding air, while relative pressure measures the deviation from this reference point. Everyday examples such as tyre pressure gauges are based on relative pressure values, not absolute values.

Applications of relative pressure

Units of relative pressure

Relative pressure is widely applied in many sectors:

- HVAC systems: Monitoring air filters and controlling airflow

- Automotive industry: Measuring tyre, fuel, and oil pressures

- Medical technology: Blood pressure monitors and respiratory systems

- Industrial process control: Monitoring liquid levels in pressurised tanks

- Water supply systems: Pump and pipeline monitoring

These examples demonstrate how relative pressure is essential for system performance, safety, and efficiency.

Relative pressure is commonly measured in:

- Pascal (Pa) = SI unit

- Bar

- Pounds per square inch (psi)

In specific industries, additional units such as millibar (mbar) or inches of water column (inH₂O) are also used.

Common sources of error in relative pressure measurement

As with all measurement methods, relative pressure readings can be influenced by external factors:

- Temperature changes: Affect gas density and diaphragm properties

- Mechanical stress: From installation or vibration

- Contamination: Dust or moisture entering the sensor port

- Calibration drift: Long-term changes requiring recalibration

High-quality sensors with robust housings and temperature compensation help to minimise these effects.

How temperature affects relative pressure

Summary

Temperature variations have a direct effect on relative pressure measurement. Rising temperatures change gas density and may cause expansion or contraction of sensor components, leading to slight output shifts. In applications exposed to fluctuating or extreme temperatures, sensors with temperature compensation are essential.

Relative pressure is one of the most widely used forms of pressure measurement in both industry and daily life. It provides practical values for process control, monitoring, and safety. By understanding the relative pressure formula, knowing what relative pressure means, and being aware of typical error sources, engineers can ensure reliable and efficient operation in a wide range of applications.

Learn more about relative pressure sensors

For practical solutions, please visit our product page on pressure sensors or contact us for tailored support.