Supply voltage – Key to reliable electronics and sensor operation

Supply voltage plays a crucial role in the functionality of electronic components and systems. Whether in industrial automation, sensor technology, or everyday devices, the right power supply voltage ensures that components perform accurately, efficiently, and safely. But what exactly does the term “supply voltage” mean—and why is it so important?

What is supply voltage?

A technical definition

The supply voltage refers to the voltage provided by a power source to an electronic device or circuit. It is the energy needed to operate electronic components such as sensors, microcontrollers, and integrated circuits. In technical terms, the supply voltage represents the electrical potential difference between two points in the circuit, usually between the positive power rail and ground.

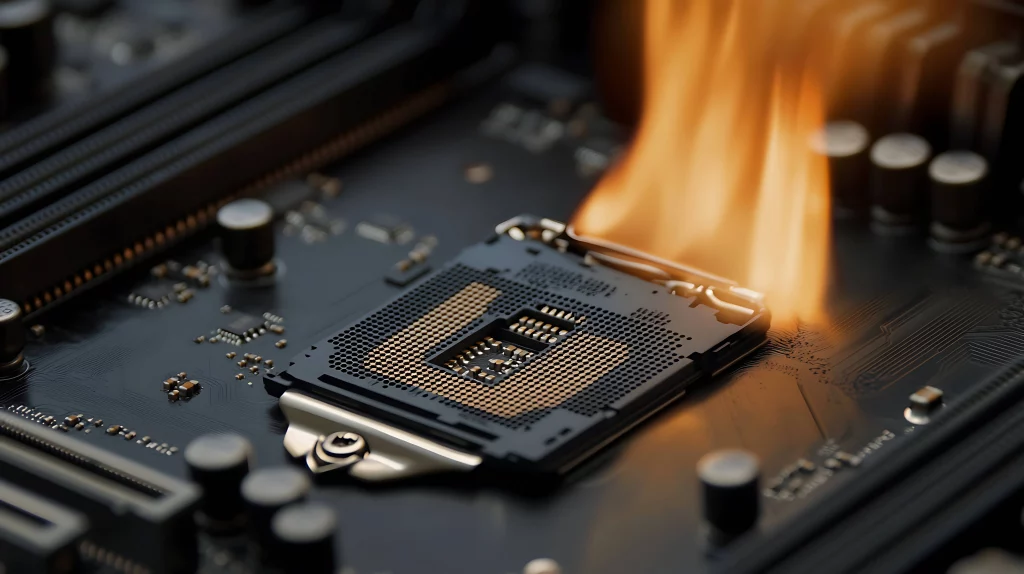

The supply voltage range describes the minimum and maximum voltage within which a device can reliably operate. Exceeding this range can lead to incorrect function, reduced lifetime, or even permanent damage.

Typical supply voltage values and examples

Different components require different supply voltages. Here are some common examples:

- Microcontrollers: typically 3.3 V or 5 V

- Operational amplifiers: ±15 V

- Digital logic circuits: 1.8 V, 3.3 V, or 5 V

- Industrial sensors: often 12 V or 24 V DC

In sensor applications, supply voltage requirements must align with the sensor type and its environment. Power supply voltage must also match the voltage output requirements of the measurement and control systems.

Why it is essential in electrical circuits

In any electrical circuit, the supply voltage determines how well individual components operate. If the voltage is too low, devices may not switch on or may produce faulty signals. If the voltage is too high, sensitive electronics—such as MEMS pressure sensors—can be damaged irreversibly. Therefore, ensuring a stable and appropriate supply voltage is one of the most fundamental aspects of circuit design.

For precision sensors, such as those developed and manufactured by All Sensors, consistent supply voltage is especially critical. Any fluctuation can affect measurement accuracy, calibration, and long-term stability.

Key parameters of supply voltage

Several parameters define the quality and suitability of a supply voltage:

- Voltage tolerance: Indicates how much variation is acceptable

- Ripple and noise: Should be minimal for high-precision applications

- Current capacity: The power supply must provide enough current for all connected components

- Stability: Fluctuations can lead to measurement errors or damage

Choosing the right supply voltage range is not just about the nominal value, but also ensuring tolerance to environmental changes like temperature or load variation.

Supply voltage as a performance-critical factor

Supply voltage is far more than just an input value—it is a decisive factor for performance, longevity, and reliability. At All Sensors, we place high emphasis on optimising sensor systems for stable and efficient operation within the specified supply voltage range. Whether you’re developing a new measurement system or optimising existing electronics, understanding and selecting the right supply voltage is essential.

Want to know how our sensors perform under different supply conditions? Get in touch with our experts. We’ll help you find or develop a sensor solution that fits your exact requirements.